Car suspension parts, incorporating advanced materials like lightweight composites and high-strength alloys, significantly enhance vehicle performance, safety, and comfort. These materials reduce weight, improve fuel efficiency, and enable precise tuning for better handling. Widely used across various vehicle types, from sports cars to rugged terrain vehicles, they also optimize exhaust systems, driving safer and more efficient vehicles forward.

“Unleash Performance with Advanced Car Suspension Parts: A Revolution in Design

Modern automotive engineering has witnessed a paradigm shift with the integration of advanced materials into car suspension systems. This evolution transcends traditional metal, introducing innovative composites and alloys that reshape vehicle dynamics. From enhanced durability to precise handling, these material breakthroughs are redefining the boundaries of car suspension parts.

Explore how these cutting-edge materials impact safety, comfort, and driving experience, revolutionizing the very essence of automotive technology.”

- Understanding Car Suspension Systems and Their Functionality

- The Evolution of Materials in Automobile Manufacturing

- Advantages and Applications of Advanced Materials in Car Suspension Parts

Understanding Car Suspension Systems and Their Functionality

Car suspension systems are a critical component of any vehicle’s overall performance and safety. These intricate mechanisms connect a car to its wheels, allowing for smooth travel over uneven road surfaces while ensuring control and stability. The primary function of car suspension parts is to absorb impacts from bumps and potholes, maintaining tire contact with the road and preventing excessive body roll during cornering. It’s a delicate balance between comfort and control that makes modern cars safer and more enjoyable to drive.

Understanding how these systems work involves recognizing their various components – including spring assemblies, shock absorbers, anti-roll bars, and more – each playing a unique role in ensuring a smooth ride. Advanced materials like lightweight alloys, high-strength steels, and even carbon fiber composites have revolutionized car suspension parts, not only improving performance but also enhancing fuel efficiency by reducing the overall vehicle weight. This evolution continues with the integration of electronic systems that further refine suspension dynamics, as seen in modern cars’ adaptive suspension technologies, which can adapt to different driving conditions and terrain.

The Evolution of Materials in Automobile Manufacturing

The evolution of materials used in automobile manufacturing has been a key driver in enhancing vehicle performance and safety. In the past, traditional metals like steel dominated the industry, forming the backbone of various components, including crucial car suspension parts. However, with advancements in engineering and material science, manufacturers have started exploring advanced materials to meet modern demands.

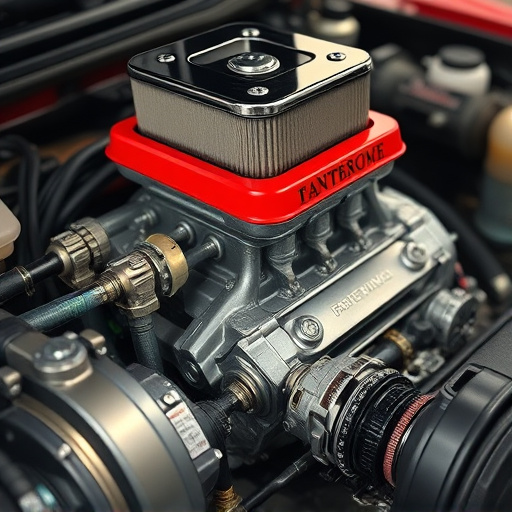

This shift is particularly evident in the development of lightweight, high-strength materials for car suspension systems. By incorporating innovative composites, such as carbon fiber reinforced polymers, manufacturers can now create lighter yet stiffer components, directly improving vehicle dynamics and fuel efficiency. This evolution extends beyond just car suspension parts; it influences a wide range of automotive systems, from brake components and exhaust mufflers to performance air filters, ultimately shaping the future of safer, more efficient vehicles.

Advantages and Applications of Advanced Materials in Car Suspension Parts

The use of advanced materials in car suspension parts offers significant advantages over traditional components. These innovative materials, such as lightweight composites and high-strength alloys, contribute to improved vehicle performance and handling. By reducing weight, they enhance fuel efficiency and lower emissions, addressing environmental concerns. In addition, their exceptional strength-to-weight ratios allow for more precise tuning of suspension systems, resulting in better cornering capabilities and a smoother ride.

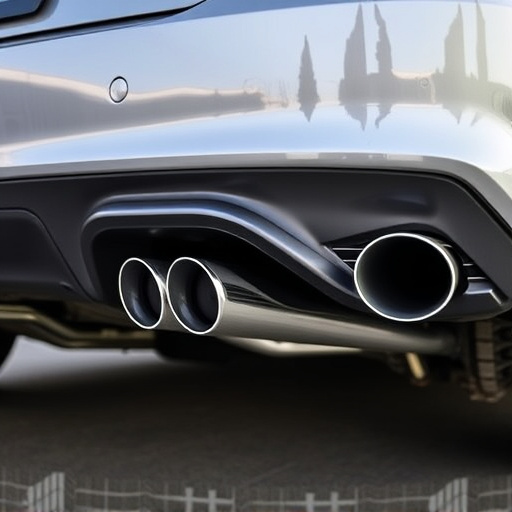

Applications of these advanced materials span across various vehicles, from high-performance sports cars to everyday family sedans. They are particularly valuable in racing and performance-oriented vehicles where every gram counts. Moreover, their durability and resistance to corrosion make them ideal for both on-road and off-road use, including rugged terrain vehicles. In the context of exhaust systems and mufflers, advanced materials also play a role in optimizing performance by reducing weight without compromising structural integrity, thereby enhancing overall vehicle dynamics.

Advanced materials are revolutionizing the landscape of car suspension parts, offering enhanced performance and safety. As we’ve explored, understanding the evolution from traditional to modern materials is key. The benefits, such as improved durability, reduced weight, and better handling, make these advanced components a game-changer in automobile manufacturing. Incorporating innovative materials like carbon fiber composites and lightweight alloys into car suspension systems allows for more efficient energy transfer, resulting in smoother rides and improved vehicle dynamics. This advancement not only benefits high-performance cars but also contributes to safer driving experiences across various vehicle types.