Car suspension parts, including shock absorbers, springs, and control arms, are critical for vehicle stability and passenger comfort. Regular inspections, advanced testing methods (like dynamic testing), and quality assurance ensure these parts meet high safety standards. Rigorous QA processes identify flaws, guarantee reliability, and optimize performance, ultimately enhancing the driving experience.

In the realm of automotive engineering, ensuring the safety and performance of car suspension parts is paramount. This article delves into the critical aspects of testing and quality assurance methods employed for these integral components. From understanding the essential elements of a car’s suspension system to exploring advanced testing techniques and implementing rigorous quality control measures, we uncover the strategies that underpin the reliability and longevity of your vehicle’s ride dynamics.

- Understanding Car Suspension Parts: Essential Components

- Testing Methods for Superior Performance and Safety

- Quality Assurance Techniques: Ensuring Reliability and Longevity

Understanding Car Suspension Parts: Essential Components

Car suspension parts are critical components that ensure a smooth ride and optimal vehicle control. These parts include shock absorbers, springs, struts, and control arms, each playing a unique role in maintaining vehicle stability and comfort. Shock absorbers, for instance, dampen road irregularities, while springs support the weight of the vehicle and control its movement. Struts, on the other hand, provide structural integrity to the suspension system.

Understanding the intricate interplay of these car suspension parts is crucial for testing and quality assurance. Regular inspections and rigorous testing methods ensure that brake rotors, performance brakes, and air filter kits—amongst others—function optimally. This includes checking for wear and tear, ensuring proper alignment, and verifying the overall integrity of each component to guarantee a safe and enjoyable driving experience.

Testing Methods for Superior Performance and Safety

When it comes to car suspension parts, rigorous testing and quality assurance are paramount for ensuring both superior performance and maximum safety. Manufacturers employ a variety of advanced testing methods to simulate real-world driving conditions, subjecting components like shock absorbers, springs, and control arms to extreme forces and stress levels. These tests not only verify the structural integrity of each part but also evaluate their ability to withstand wear and tear over extended periods.

Beyond ensuring basic functionality, testing protocols often incorporate assessments of dynamic behavior, such as handling and ride quality, to guarantee that car suspension parts contribute to a smooth and responsive driving experience. Additionally, safety-critical components like brake rotors and intake components are subjected to stringent performance evaluations, including fatigue tests and durability simulations, to prevent failures that could compromise the well-being of drivers and passengers. Even aftermarket modifications, such as cold air intakes, undergo similar scrutiny to ensure they meet the same high standards of quality and safety as original equipment parts.

Quality Assurance Techniques: Ensuring Reliability and Longevity

In the quest for exceptional car suspension parts, Quality Assurance (QA) techniques play a pivotal role in ensuring reliability and longevity. These rigorous processes are designed to uncover potential flaws or defects at each stage of manufacturing, from material procurement to final assembly. By implementing advanced testing methods, manufacturers can guarantee that every component meets stringent industry standards and performs optimally under various driving conditions.

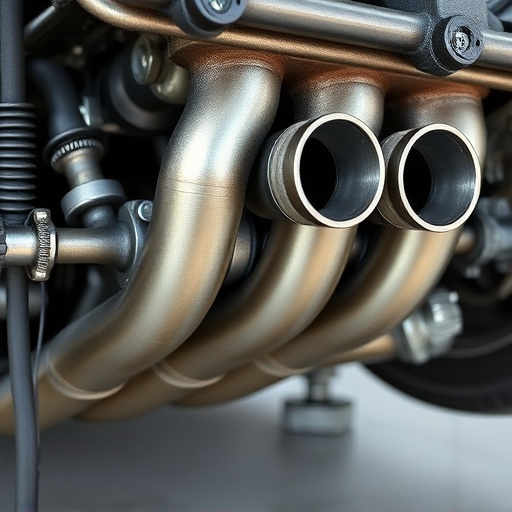

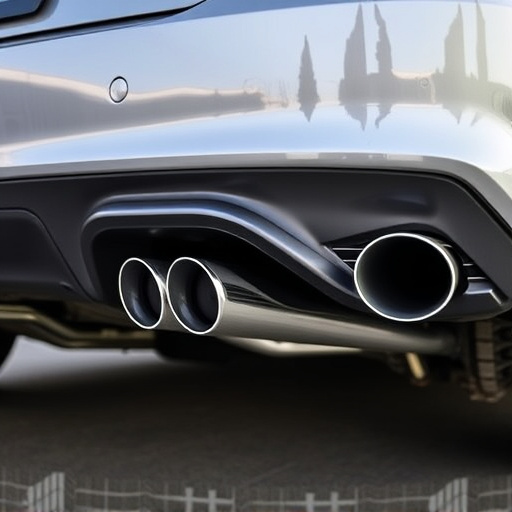

Among the QA techniques employed for car suspension parts, dynamic testing stands out. This involves subjecting parts to simulated road conditions, including cornering, braking, and acceleration, to assess their durability and responsiveness. Additionally, non-destructive testing methods, such as ultrasound and magnetic particle inspections, help identify internal structural flaws without damaging the components. Furthermore, the integration of performance brakes, cat-back exhausts, and performance exhaust systems during QA testing can provide valuable insights into overall vehicle performance and handling, ensuring that these critical subsystems work in harmony with the suspension to deliver a seamless driving experience.

Car suspension parts play a critical role in vehicle performance, safety, and longevity. Testing methods and quality assurance techniques are indispensable for ensuring these components meet high standards. By employing advanced testing procedures and rigorous quality control measures, manufacturers can guarantee the reliability and durability of car suspension parts, enhancing overall driving experience and passenger safety.