Car suspension parts are critical for performance, handling, and comfort. Key components include springs, shock absorbers, control arms, and coilover kits. Testing methods use dynamic tests, simulations, and advanced machinery to ensure safety, precision, and compatibility. Rigorous protocols, feedback integration, and continuous improvement enhance quality assurance for reliable, long-lasting car suspension parts.

In the automotive industry, ensuring the safety and performance of car suspension parts is paramount. This article delves into the intricate world of testing and quality assurance methods for these critical components. From understanding the essential elements of a car’s suspension system to exploring advanced testing techniques and implementing robust quality control measures, we uncover the strategies that maintain ride quality, handling, and overall vehicle stability. Discover how meticulous processes safeguard drivers and enhance vehicular durability.

- Understanding Car Suspension Parts: Essential Components

- Testing Methods for Suspension Systems: Safety and Performance

- Quality Assurance Techniques: Ensuring Reliability and Longevity

Understanding Car Suspension Parts: Essential Components

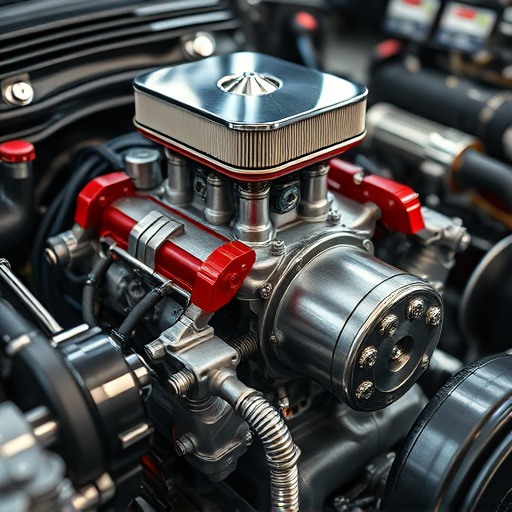

Car suspension parts are integral to a vehicle’s performance, handling, and comfort. These critical components work in unison to ensure smooth travel over varying terrains. The primary suspension systems include spring and shock absorbers, which absorb road impacts and maintain tire contact with the pavement. Other essential car suspension parts involve control arms, ball joints, and bushings, enabling steering and managing wheel movement relative to the chassis. Advanced vehicles may feature sophisticated systems like coilover kits that offer precise height adjustment and enhanced cornering capabilities, while accessories such as cold air intakes and exhaust systems, though not direct suspension components, can indirectly influence vehicle dynamics by affecting engine performance and weight distribution.

Testing Methods for Suspension Systems: Safety and Performance

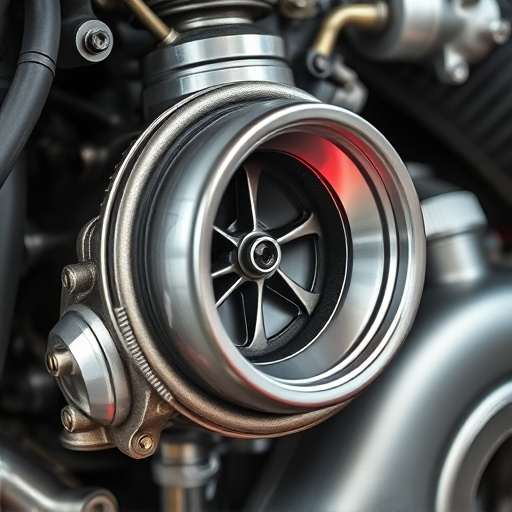

Testing methods for car suspension systems are paramount to ensuring both safety and optimal performance. These rigorous evaluations go beyond basic functionality checks to include dynamic tests that mimic real-world driving conditions. By subjecting suspension parts to stress, fatigue, and impact simulations, manufacturers can validate their design effectiveness and predict longevity under varying road conditions. Advanced technologies like computer-aided engineering (CAE) simulations and hardware-in-the-loop testing play a crucial role in this process, enabling engineers to analyze and refine car suspension parts before mass production.

The focus on high-performance parts extends beyond the suspension system itself. Integrating components such as exhaust mufflers and brake rotors also demands meticulous quality assurance. These critical elements contribute significantly to overall vehicle dynamics, affecting handling, braking efficiency, and noise levels. Thorough testing ensures not only their functionality but also their compatibility with the suspension system, ultimately securing a seamless driving experience that meets or exceeds performance expectations.

Quality Assurance Techniques: Ensuring Reliability and Longevity

In the realm of car suspension parts testing and quality assurance, employing robust techniques is paramount to ensure reliability and longevity. Rigorous protocols include thorough inspection of each component under various stress conditions, simulating real-world driving scenarios to gauge performance and durability. This meticulous process involves advanced machinery capable of precise measurements, allowing for the identification and correction of even subtle defects that could compromise safety or performance over time.

Beyond basic inspections, sophisticated methods such as vibration testing, temperature cycling, and fatigue tests are implemented to simulate extreme conditions. These techniques not only uncover potential weaknesses in car suspension parts but also ensure they meet stringent industry standards. Furthermore, integrating feedback from real-world applications, including data from air intake systems, muffler tips, and brake components, allows for continuous improvement and refinement of quality assurance processes.

Car suspension parts play a critical role in ensuring vehicle safety, handling, and longevity. Through rigorous testing and stringent quality assurance methods, manufacturers can verify the performance and durability of these essential components. By employing advanced testing techniques, such as dynamic simulation and failure analysis, along with meticulous quality control measures like precision machining and material selection, the automotive industry can deliver reliable car suspension parts that contribute to a smooth ride, precise steering, and overall vehicle stability.